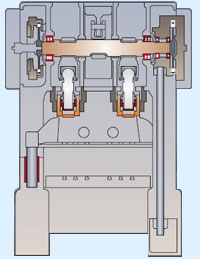

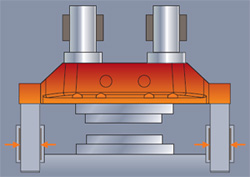

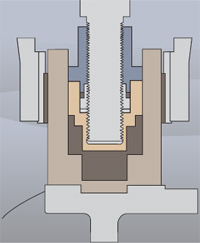

All Models exceed the JIS Class “Special” precision standards and incorporate features like Plungers & Post Guides in hydro-static guide bushes, dynamic balancer, motorized slide adjustment with readout and interlocked hydraulic locking, closed-loop lubrication system with filtering and chilling, microprocessor controls with touch screen programming, feedback, fault indication and built-in interfacing with tool / process monitors and auxiliary equipments.

All presses are supplied as fully integrated lines with stock handling, High Speed feeders, Die Monitors, Die change systems etc. |